E-TORQUE’s Electronic Fuel Injection Systems

E-Torque needed to develop various EFI systems to leverage the potential from its Cylinder Heads.

Carburetors are only accurate at two points - idle and cruise, as there are only two jets on most carbs. Jetting is an imperfect science because it is based upon static air temperature, barometric pressure and humidity. As a result, if your car is relying upon carburetor, most of the time, it is technically out of tune. Jaguar put wing nuts on an easily removable plenum because they wanted to make the SU carburetors easily accessible for technicians to tune and balance on an E-type.

By comparison, Electronic Fuel Injection (EFI) guarantees that your air/fuel mixture is pretty ideal at all times. Modern ECU’s update the mixture, fuel injection timing and spark timing many times per second. This has made internal combustion engines cleaner, more environmentally friendly, reliable, and most of all, more powerful. Because EFI does not rely upon vacuum to pull fuel into the engine, it can support more aggressive cam profiles than carbs can. This electronic fuel injection system can make high-performance cams idle smoothly and have reasonable low speed drivability that carbs cannot handle for street driving.

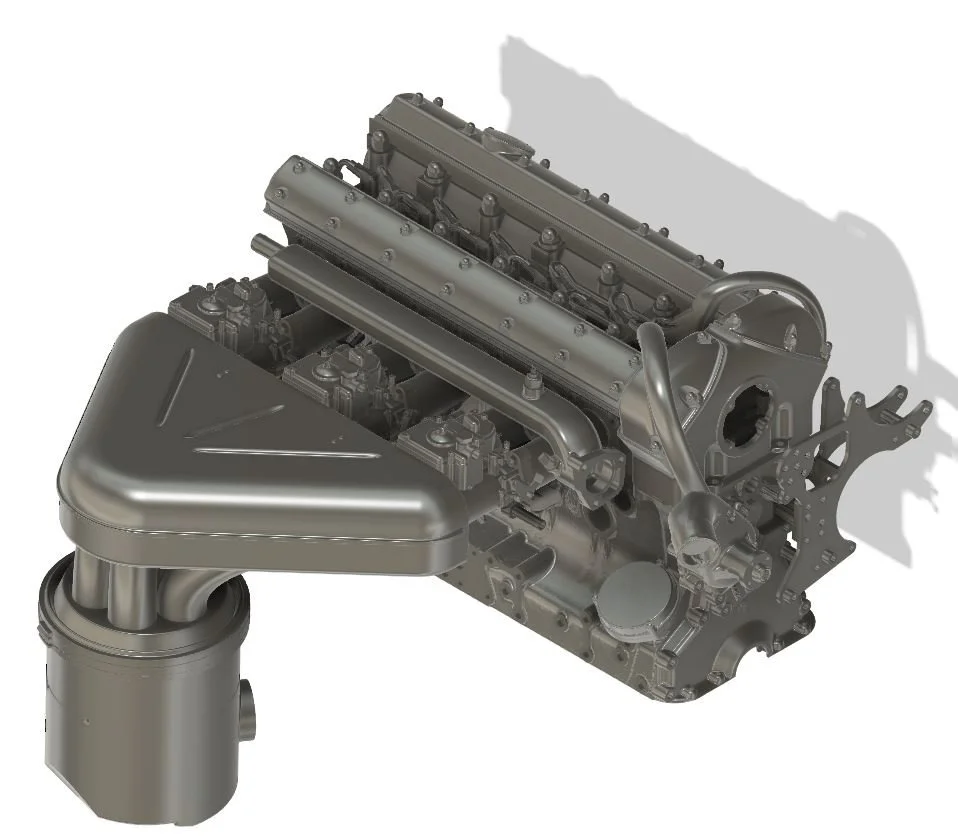

E-Torque manufactures three EFI systems. Two of these systems are for the E-type exclusively where one is based upon an SU appearance and the other uses real Weber DCOE carburetor bodies with their venturis removed. We have also developed a third EFI system for XK and XJ6 cars, which is based upon a Weber layout using custom throttle bodies that fit the tight spaces of their engine compartments. Each induction system has a custom pre-induction system (air filtration) that draws cold air from in front of the car. This electronic fuel injection for cars is essential to a high performance system.

E-Torque has developed specialized EFI systems for the Jaguar XK engine:

A retro-style EFI system based on the SU carburetor for E-types

A retro-style EFI system based on the Weber carburetor for E-types

A retro-style EFI system based upon custom throttle bodies using Weber standards for XK & XJ6.

Both the SU and Weber carburetors were commonly used in all Jaguar XK cars.

Additional Information about E-Torque EFI Systems:

All systems use a custom intake manifold casting that separates the water jacket from the air passages to keep the incoming air charge cooler and able to hold more fuel

Our Intake manifold castings have polished water manifolds as the original, have straight port designs, and are significantly lighter than the original or other aftermarket castings.

All intake manifolds have the fuel injectors hidden under the air passages to maintain a vintage appearance.

The SU-based EFI system for E-type uses three 60mm custom billet aluminum throttle bodies.

The Weber-based EFI system for E-type uses three real 45 - 50mm Weber DCOE carburetors.

The XK & XJ systems use three 45mm custom throttle bodies depending on displacement.

All systems have built-in idle air control (IAC), Inlet Air Temp (IAT), Manifold Absolute Pressure sensing (MAP), Coolant Temp sensing (CT) and Throttle Position Sensor (TPS).

All EFI hardware is sold in a Hardware Kit by application for a specific car.

All Electronic Systems are sold in an Electronics Kit by application for a specific car.

All ECU’s come with profiles for basic tuning. Car specific tuning is done on a chassis dyno by others.

Each EFI system has an accompanying Pre-Induction (air filtration) system. These components draw air from an ambient source ahead of the radiator and duct it to the inlet of an air filter housing. These housings are sized to the maximum power rating of any E-Torque XK engine. All air filter elements are custom designed and produced solely for E-Torque. Although these air filter elements are washable, E-Torque will sell replacement elements.

All classic Jaguar cars were hand built and variances of up to a half inch are common between cars. For this reason, anyone buying a pre-induction system must be ready to adapt it to his car - should variances make that difficult. Because our parts are 3D printed, we can make adjustments.